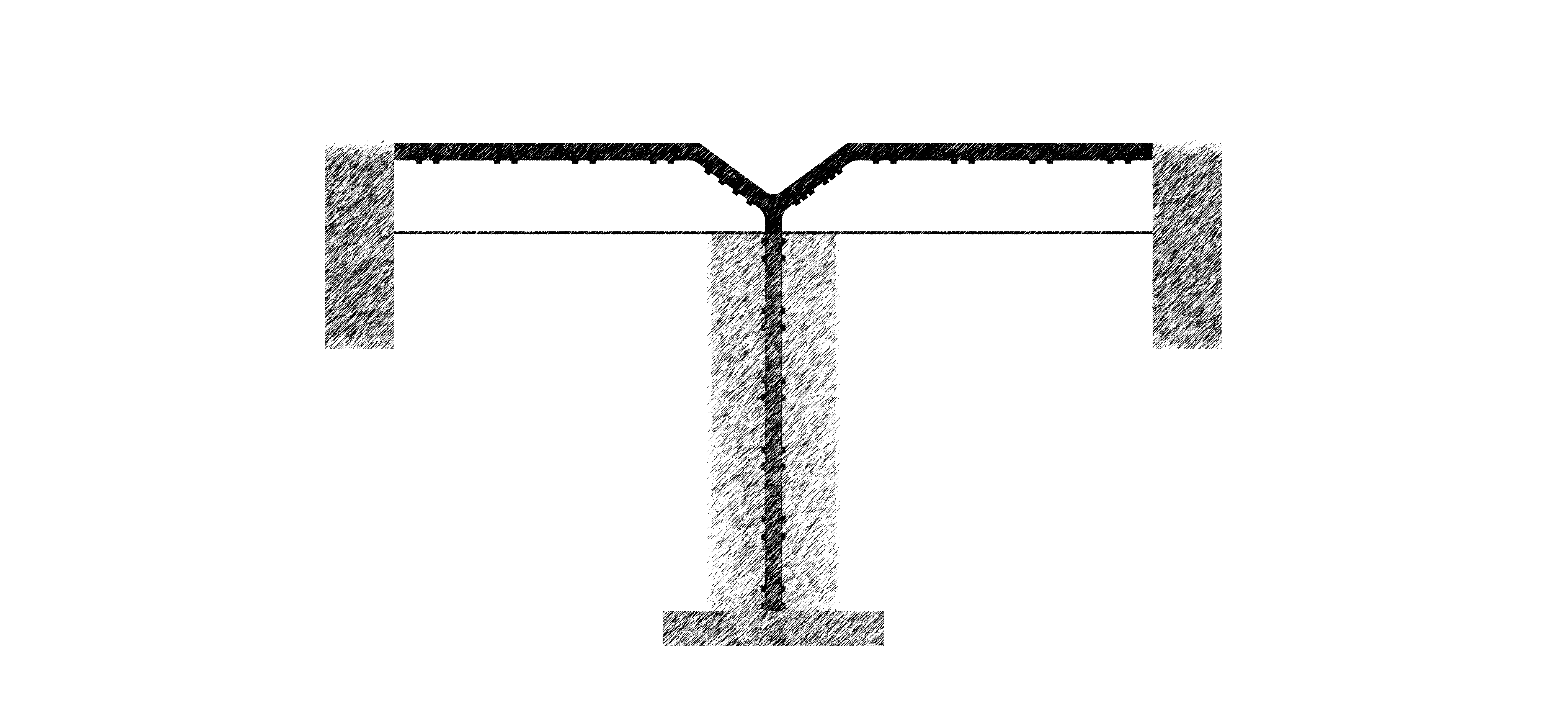

Advanced Air Inlet System

The Synergic Plant's air inlet system is designed to maximize gas turbine performance while minimizing degradation and maintenance costs.

Filtration and Chilling System

Optimized Inlet Ducting

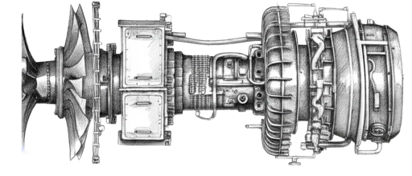

Aero-derivative Gas Turbines

The Synergic Plant employs aero-derivative gas turbines renowned for their exceptional flexibility, rapid startup capability, and high reliability. Compared to industrial turbines, these turbines offer quicker responsiveness, making them ideal for dynamic load management.

Gas Turbine Exhaust

The Synergic Plant features a proprietary high-temperature refractory exhaust design that merges directly with the OTSG base.

Key Advantages:

Extended Length Design

Heat Retention

Noise Reduction

Improved Performance

Lower Maintenance

Once Through Steam Generators

The Synergic Plant integrates state-of-the-art Once-Through Steam Generators (OTSGs) from Innovative Steam Technologies (IST). OTSGs are a key factor behind the Synergic Plant's fast starts and high efficiency.

Key Benefits:

Rapid Startup and Shutdown

Full Dry Running Capability

Cold-Weather Ready

Impulse Type Steam Turbine

The Synergic Plant's steam turbine is a two-pressure impulse-type design optimized for flexibility and reliability.

Impulse Design Advantages:

Fast Start/Stop Cycles

Wide Operating Range

Lower Operating Temperatures and Pressures

Reduced Maintenance

Synergic Super Core Condenser (SCC)

The proprietary Synergic SCC dramatically improves steam cycle performance, matching the characteristics of the aero-derivative gas turbines and OTSG.

Highlights of the Synergic SCC include:

SynVane Coolers

The SynVane Coolers are a critical part of the advanced air cooling system that provides the efficiency of a water-cooled plant while virtually eliminating water consumption. This technology is a key enabler of the Synergic Plant's flexible siting and superior environmental performance.

Key Advantages:

High-Efficiency Performance

Superior Environmental & Community Profile

Flexible and Scalable Design

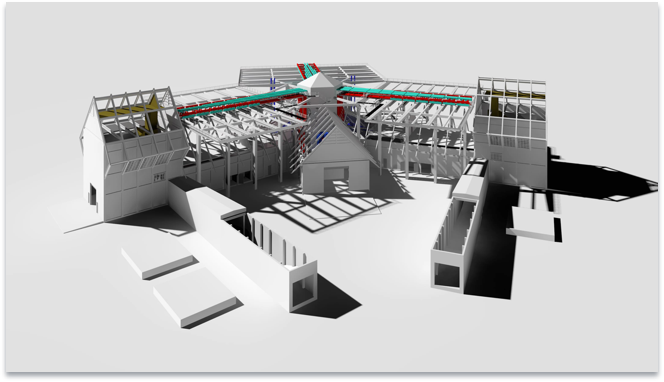

Tri-form Building

The Tri-form Building is a unique 120° structure that houses all plant equipment in a sound-absorbing, climate-controlled enclosure while also actively improving system performance and efficiency.